Small Spangle: The crystal pattern is small, with a diameter of about 1-3mm, and needs to be observed up close.

Non Spangle: There are no obvious crystalline patterns on the surface, and the appearance is uniform and smooth.

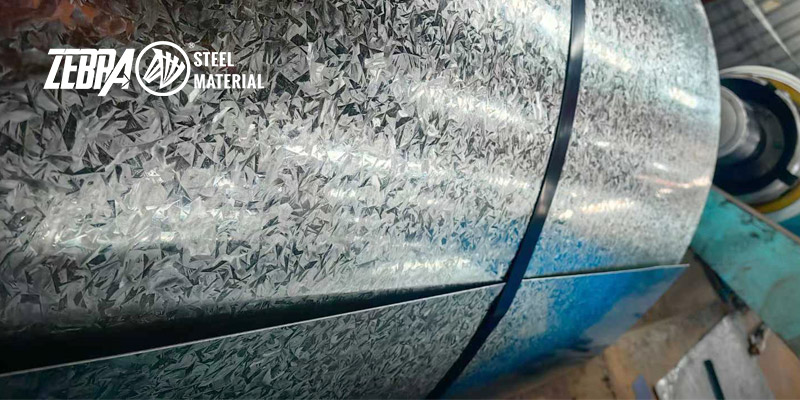

Big Spangle: By controlling the cooling rate, the zinc liquid slowly crystallizes.

Small Spangle: accelerates cooling speed and promotes fine crystallization.

Non Spangle: using special processes (such as air knife blowing) to suppress the formation of zinc flowers.

Big Spangle: commonly used in buildings, agriculture, and other places where surface requirements are not high.

Small Spangle: Suitable for fields such as home appliances and automobiles that require good surface quality.

Non Spangle: used in industries with strict surface requirements such as high-end home appliances and automobiles.

English

English