FAQ

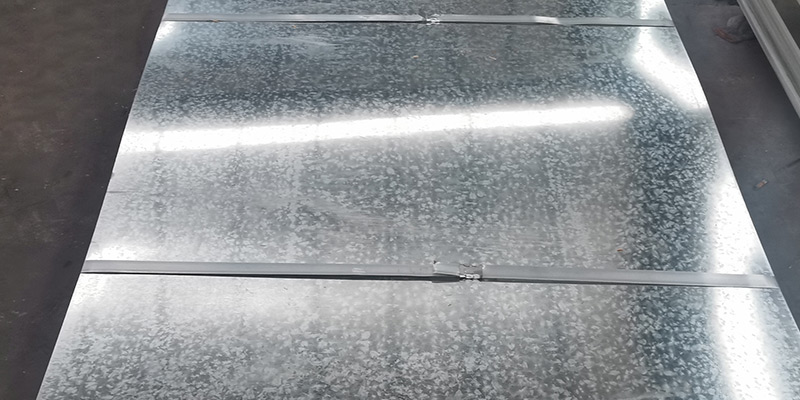

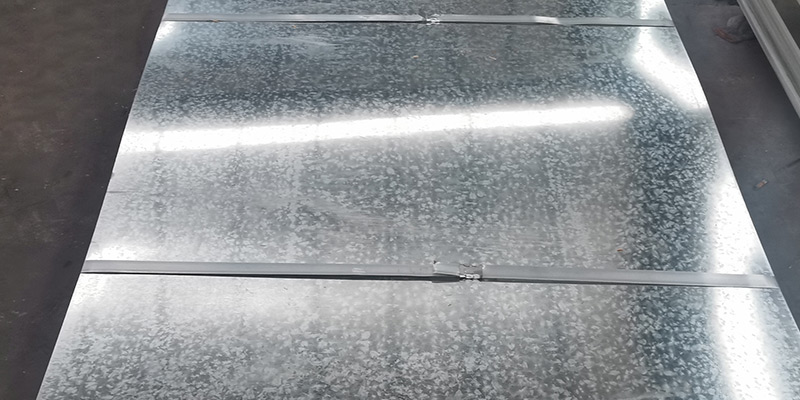

The difference between different grades of galvanized sheet

Release time:2025-02-28

The different grades of galvanized sheet are mainly divided based on the thickness of the galvanized layer, surface quality, mechanical properties, and usage. The following are common levels and their differences:

1. According to the thickness of the galvanized layer

Regular Spangle: The galvanized layer is relatively thin and suitable for situations where general rust prevention requirements are not high.

Advanced (Minimized Spangle): The galvanized layer is thicker, with better rust prevention performance, suitable for outdoor or high humidity environments.

2. According to surface quality

Prime surface: Smooth surface with no obvious defects, suitable for high-quality applications such as household appliances and automobiles.

Secondary surface (Commercial): allows for a small number of defects, suitable for buildings and industrial equipment with low surface requirements.

3. According to mechanical properties

Commercial Steel (CS): The strength is average and suitable for ordinary structures.

High Strength Steel (HS): With high strength, it is suitable for structures that need to withstand large loads.

4. By purpose

Galvanized sheet for construction: with good rust resistance, commonly used for roofs and wall panels.

Galvanized sheet for household appliances: with high surface quality, used for household appliance casings.

Galvanized sheet for automobiles: with high requirements for strength and corrosion resistance, used for body components.

5. According to the galvanizing process

Hot Dip Galvanized (HDG): The coating is thick and has strong corrosion resistance.

Electro Galvanized (EG): The coating is thin, the surface is uniform, and it is suitable for fine processing.

6. According to standards

ASTM standards, such as ASTM A653, are divided into multiple levels (such as G60, G90).

JIS standards, such as JIS G3302, are divided into multiple levels (such as SGCC, SGHC).

EN standards, such as EN 10346, are divided into multiple levels (such as DX51D, DX52D).

Summarize

The different grades of galvanized sheet are mainly reflected in the thickness of the galvanized layer, surface quality, mechanical properties, and applications. The selection should be based on specific needs and application environments.

English

English