Base Material – Cold-rolled steel coil.

Galvanization – Coated with a layer of zinc (hot-dip galvanized or electro-galvanized) for rust protection.

Chemical Treatment – A passivation layer (e.g., chromate or phosphate) is applied to enhance paint adhesion.

Primer & Paint Coating – Multiple layers (primer, topcoat, and sometimes a backer coat) are applied via a continuous coil coating line, followed by baking for durability.

Protective Film – A removable plastic film may cover the surface to prevent scratches during transport.

Corrosion Resistance – Zinc layer protects against rust.

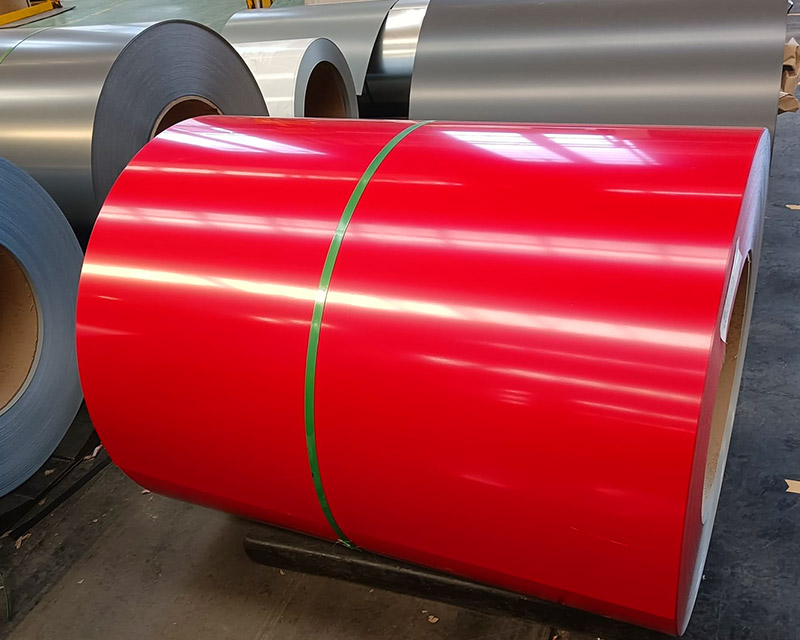

Aesthetic Appeal – Available in various colors, gloss levels, and textures.

Durability – Resistant to UV rays, weathering, and scratches.

Formability – Can be bent, stamped, or rolled without cracking the paint.

Cost-Effective – Pre-painting eliminates the need for post-fabrication painting.

Roofing & Wall Cladding – Used in industrial, commercial, and residential buildings.

Appliances – Refrigerators, washing machines, and air conditioners.

Automotive Parts – Interior panels and trim components.

HVAC Ducts & Electrical Enclosures – Combines protection with a finished look.

Metal Furniture & Signage – Provides a decorative, long-lasting surface.

✔ Uniform Coating – Factory-applied paint ensures consistent quality.

✔ Faster Installation – No on-site painting required.

✔ Eco-Friendly – Reduced VOC emissions compared to wet painting.

Common standards include ASTM A755 (for prepainted steel) and EN 10169. Thickness typically ranges from 0.2mm to 1.5mm, with coatings measured in microns (e.g., 20-25μm paint layer).

Would you like details on specific colors, coatings, or suppliers?

English

English