As a composite material widely used in fields such as construction and home appliances, the impact resistance of color coated steel sheet is one of the important indicators for measuring quality.

In order to accurately evaluate the impact resistance of color coated steel, certain testing standards need to be followed. We will provide a detailed introduction to the standards and related content of impact testing for color coated sheet.

1. GB/T 1732-1993 "Determination of Impact Resistance of Coatings": This method uses a fixed mass heavy hammer to freely fall and impact the coating film, and represents the impact resistance of the coating film at the maximum height that does not cause damage to the coating film.

2. ASTM D 2794-1993 (1999) "Effect of Organic Coatings on Resistance to Rapid Deformation (Impact)": This method uses an impact coating and its substrate to rapidly deform and evaluate the effect of this deformation. By continuously increasing the drop height of the heavy hammer until the coating ruptures, the impact resistance of the coating is determined.

3. ISO 6272:1993 (E) "Paints and varnishes - Drop hammer test": This method is similar to ASTM D 2794 and evaluates the impact resistance of coatings through the drop hammer test. The difference is that ISO standards place more emphasis on the standardization of equipment and the reproducibility of test results.

Test conditions: It should be ensured that the test environment meets the standard requirements, including temperature, humidity, etc. At the same time, it is necessary to ensure that the state of the PPGI Steel or PPGl Steel is similar to the actual application state to improve the accuracy of the test results.

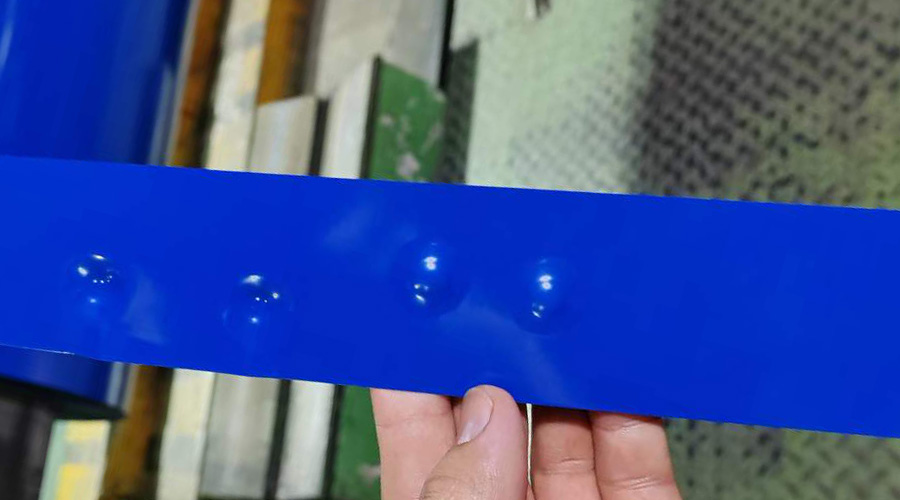

Prepainted steel preparation: The color coated steel should be flat, free of oil stains and damage, and the size should meet the standard requirements. When sampling, extra stress or deformation should be avoided on the specimen.

Operating standards: Operators should be familiar with the operating methods and precautions of the testing equipment to ensure the stability and accuracy of the equipment during the testing process. At the same time, standard experimental procedures should be followed to avoid the influence of human factors on the test results.

Guidance on production: Through impact testing, the impact resistance performance of color coated plates under different conditions can be understood, providing guidance for material selection and process optimization in the production process.

Quality control: Impact testing can be an important part of color coated steel quality inspection to ensure that the product meets relevant standards and customer requirements.

Safety of use: Understanding the impact resistance of color coated steel can help evaluate their safety and reliability during use, providing a basis for rational use and maintenance.

The impact testing standard for color coated steel is an important basis for evaluating their impact resistance performance. By understanding and following these standards, we can better ensure the quality and safety of prepainted galvanized/galvalume steel.

English

English